| Availability: | |

|---|---|

| Quantity: | |

WJ-III

WINCOO

The WJ-III Swinging Corner Welding Machine, designed to meet the needs of a wide range of industries including shipbuilding, bridges, locomotives, steel structures, and petrochemicals. This versatile machine is capable of welding various structures ranging from reinforcing plates to rib plates, cross joints, and box beams. The WJ-III is the perfect solution for welding tasks that require precision and efficiency. With its advanced features and durability, this machine guarantees to provide high-quality welding performance. It is the ideal tool for professionals who demand the best in their welding equipment. Get your hands on the WJ-III Swinging Corner Welding Machine today and experience the difference in your welding tasks.

1, Equipped with advanced welding technology, the WJ-III Swing Corner Welder boasts high-performance features that ensure precise and efficient welding results. Its swing angle can be adjusted according to the welding requirements, providing greater flexibility and accuracy in welding different structures. The machine also comes with a stable and adjustable fixture that can hold the workpiece in place to avoid any displacement during the welding process.

2, The WJ-III Swing Corner Welder is easy to operate, with simple controls and user-friendly interface. Its compact design allows for easy transportation and storage, making it an ideal welding solution for both indoor and outdoor applications.

3, Whether you need to weld steel structures for a bridge or reinforce plates for a ship, the WJ-III Swing Corner Welder is the perfect tool for the job. It delivers consistent and high-quality welds every time, ensuring the integrity and safety of your structures.

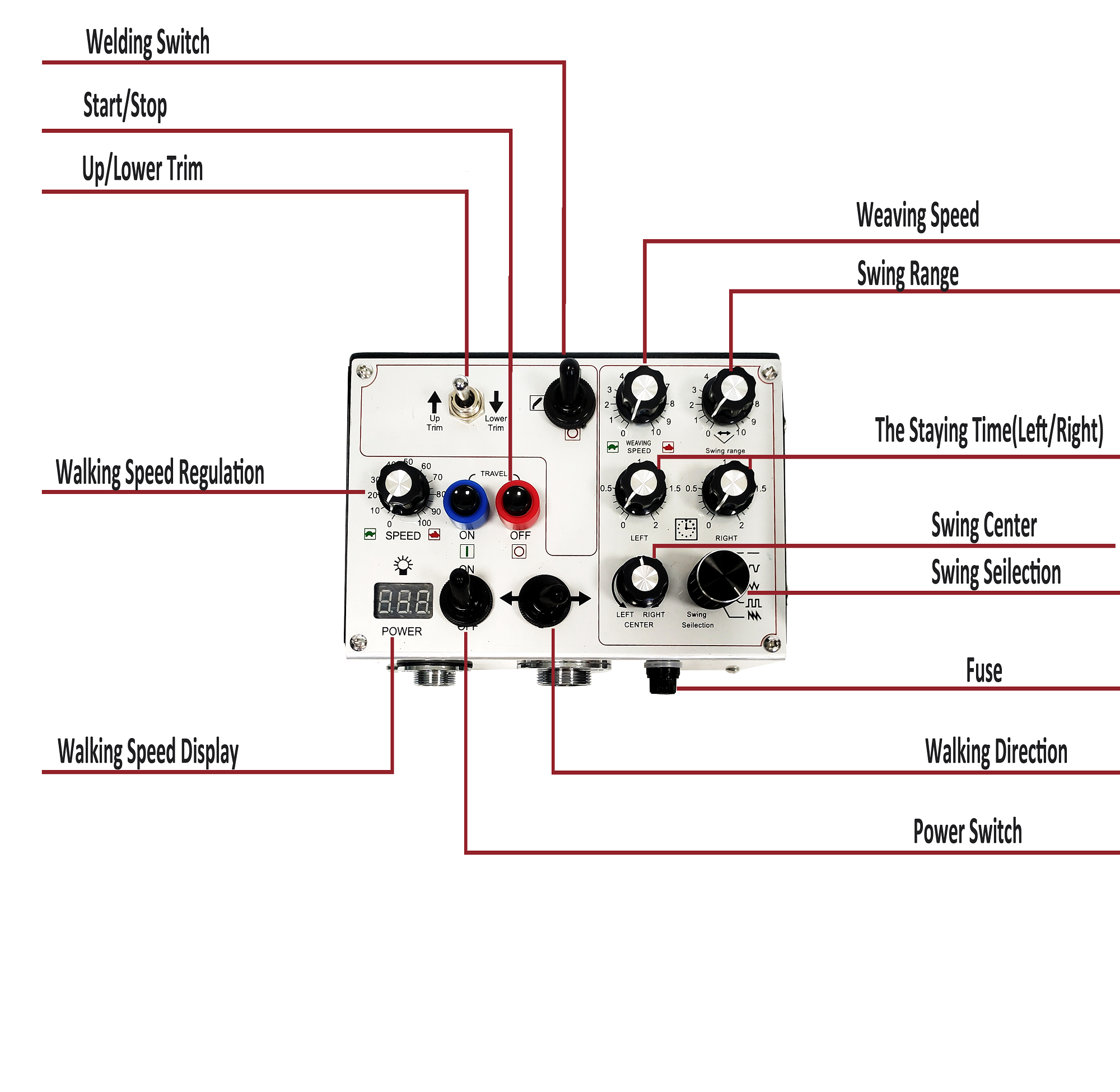

These are the essential components of the welding system: a swing device for pendulum welding, a slider to fine-tune the welding gun's position, a welding gun handle, a control box and panel, and additional accessories.

1. Pendulum Swing Device: This device powers the welding gun's back-and-forth motion for pendulum welding.

2. Trolley Drive Mechanism: The trolley's drive system comprises four magnetic wheels, helical gears, chains, and sprockets.

3. Slider Unit: This component adjusts the welding gun's position, enabling precise positioning before and during welding.

4. Welding Gun Fixture: This clamping system adjusts the welding gun's angle.

5. Guide Wheel: The guide wheel ensures the trolley follows the welding line accurately.

6. Magnetic Handle: An added convenience for ease of movement and installation.

7. Control Box: This box allows you to adjust all trolley movements. Please refer to the control panel manual for details.

8. Stop Switch: The stop switch triggers when the welding reaches the end of the workpiece, halting the trolley's movement.

| Items | Parameter | Note | |

| Tractor | Power supply | AC 220V | |

| Size | 240×330×310 mm | W×L×H | |

| Weight | 12 Kg | Including swinger | |

| Moving mode | Four-wheel drive | Rubber-wheel | |

| Walking speed | 0∼880mm/min | ||

| Control | Swing motor | DC24V 18RPM | |

| Adjustable range of welding gun | Up and down | ||

| Before and after | 85mm | ||

| Operating Angle adjustment range | 360° | ||

| Carry out Angle adjustment range | 0° | ||

| Operating function | Swing mode | ||

| Swing speed | 0-10RPM(Show with scale) | ||

| Swing scope | 0-±10°(Show with scale) | ||

| Left and right residence time adjustment | 0-2S(Show with scale) | ||

| Central range of movement | 0-±8° | ||

| Inching wire feeding | |||

| Walking starts/stops | |||

| Welding current/voltage control | |||

| Choice of walking direction | |||

| Walking speed regulation | 0∼1000mm/min(Show with scale) | ||

| Welding/non-welding options | |||

Detailed Description of Simple Chain Type Hydraulic Jacking System

Detailed Description of Simple Chuck Type Hydraulic Jacking System

Detailed Description of Advanced Three-Stage Hydraulic Jacking System

Detailed Description of Advanced Two-stage Hydraulic Jacking System

What is the meaning of the solution of container pipe spool fabrication line?

What is the significance of the solution of container pipe spool fabrication line?

Outlook on sales of hydraulic lifting machine in the second half of the year

Sign up for our newsletter to receive the latest news.

Copyright © 2020 WINCOO ENGINEERING CO.,LTD

Support By:Leadong