| Availability: | |

|---|---|

| Quantity: | |

NSHW-I

WINCOO

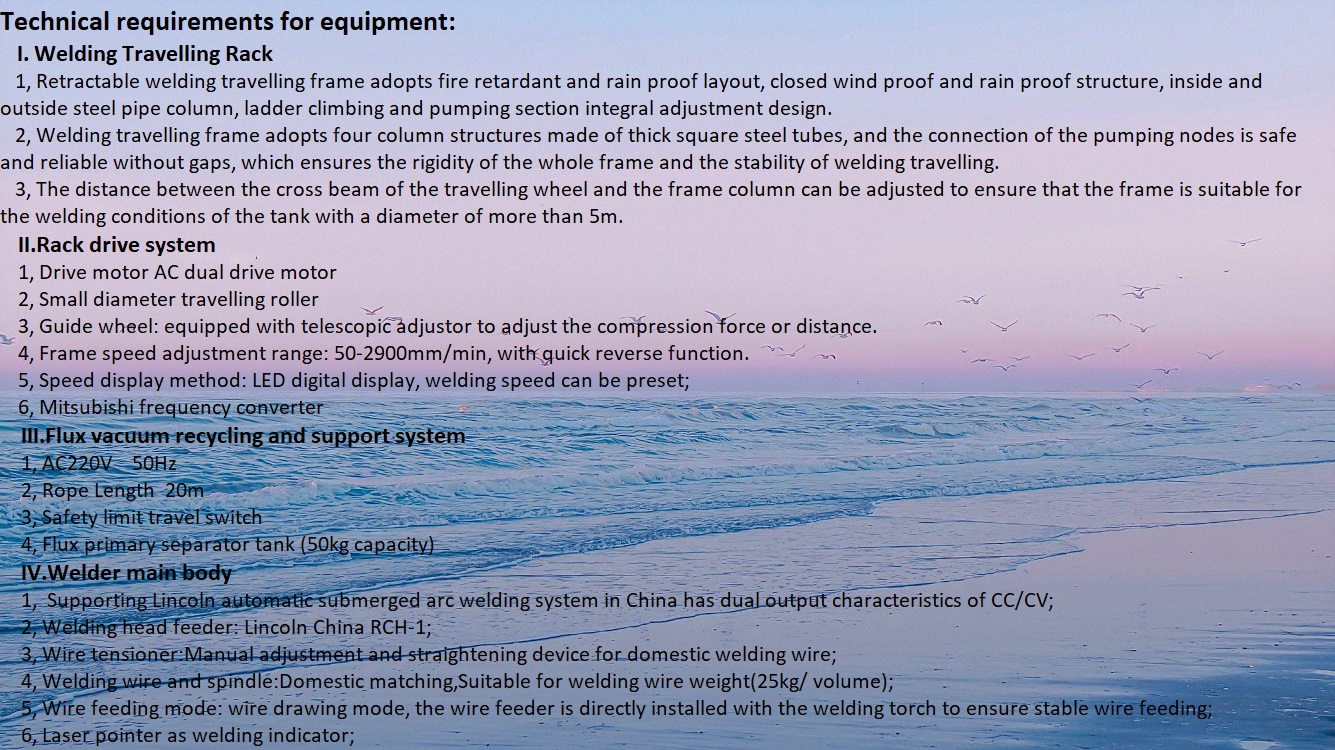

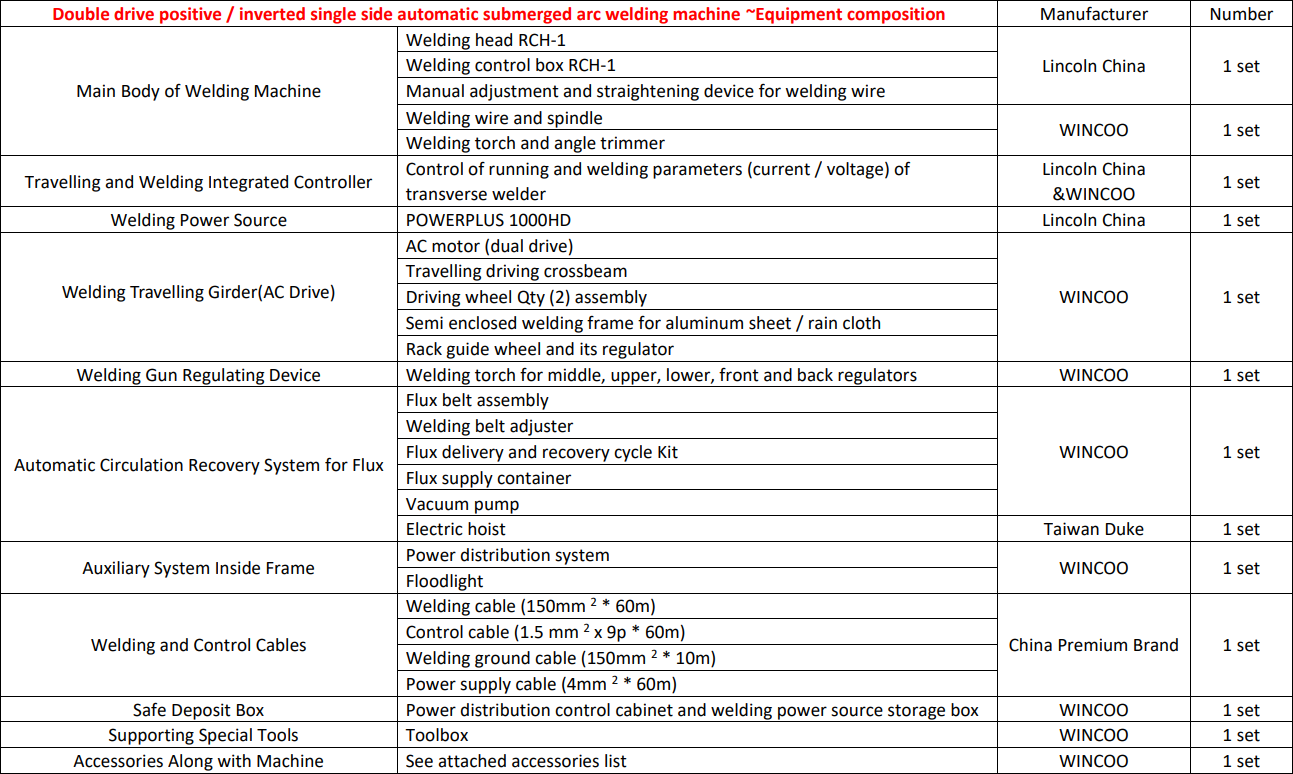

WINCOO Engineering offers the Automatic Girth Welder for tank fabrication applications.Unlike current girth welders on the market,the MSHW series comes standard with a Dual Drive System.This self-propelled submerged arc welding system can reduce field storage tank welding time up to 40%.Weld defects are greatly reduced,saving tank erection costs.The Girth Welder is applicable for top down or bottom up construction single or double wall storage tanks for inside and outside welding.There are four standard units,however our design allows us to offer custom built units for non-standard application.

For the tank welding machine, we has been sold more than 20 countries in more than 1000 projects sites.We have confidence for the machine quality and after sale service. We can provide single side, double side crude oil, LNG tank, fuel tank, water tank horizontal seam, vertical seam and bottom plate/corner welding machine.In Middle East, we have sold to UAE, Saudi Arabia, Oman, Bahrain, Kuwait. In Africa, we have sold machine to Cameron, Sudan, Egypt, Senegal, Nigeria,Zambia,Ethiopia,Senegal,etc. We have sold to vietnam, Indonesia , Malysia,Philippines,Singapore, Mexco,Mogulia, Russia,etc.

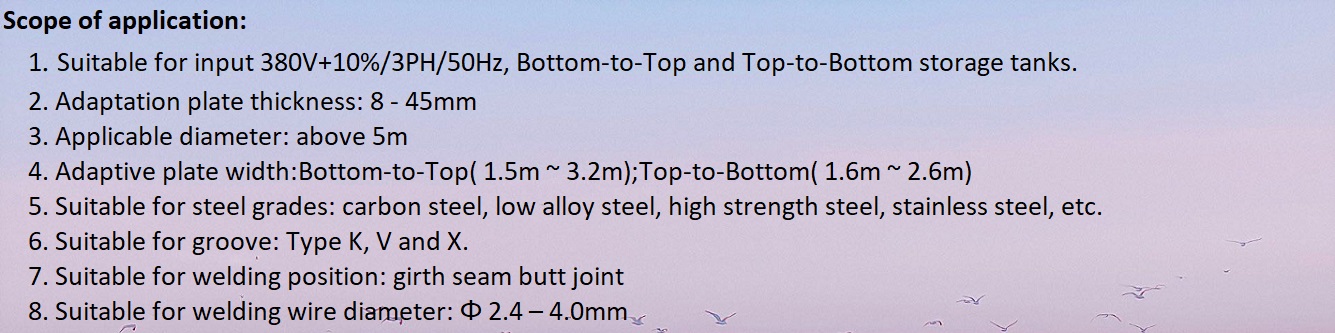

Welding Process | SAW |

Model | MSHW-I |

Plate Thickness | 8 – 45mm |

Plate Material | Carbon steel, Stainless Steel |

Groove | K groove |

Seam Position | Girth weld |

Min Tank Diameter | Φ5.0m |

Plate Width | 1.5 – 2.5m |

Power Input | 380V/3PH/50HZ |

Erection Method | Bottom To Top |

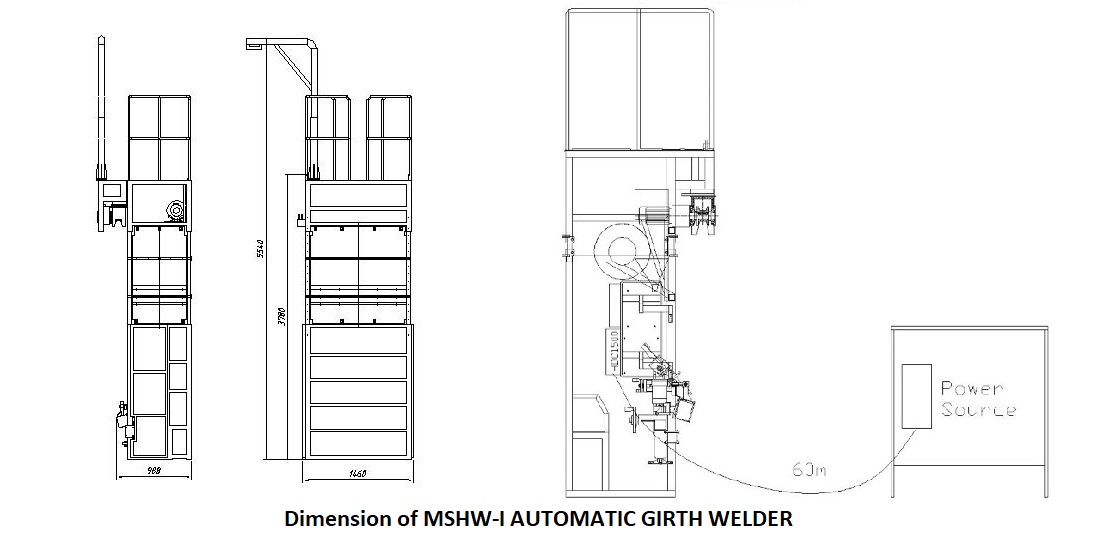

Dimension(L x W x H) | 1460mm x 988mm x 2760mm(if design change, will as per new design) |

Gross Weight | 800kg |

Wincoo Engineering Co., Ltd (WINCOO) is engaged in bringing the most suitable solutions/equipments for client, fabricators, EPC/C companies on pipe fabrication, tank construction, pipeline construction,industrial production lines, clean energy project and other industrial field.

We have ability of providing workable solutions to support clients to be awarded with shorter project execution time, fewer man-hour cost and higher efficiency construction/fabrication method and better quality during phase of project bidding.Based client's facility/site space availability, we are able to study/design and present matched configurations on project schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.

Sign up for our newsletter to receive the latest news.

Copyright © 2020 WINCOO ENGINEERING CO.,LTD

Support By:Leadong